Extrusion

Extrusion is such a continuous process that makes it possible to manufacture a theoretically infinitely long, semi-finished product. It uses an ideally planned screw or a piston that presses the rubber mixture through a hole of certain width.Technologies can be categorised based on the fact if rubber material is added in pieces or in a pre-heated way.

Screws have three different zones: (1) the feeding zone that is responsible for taking rubber material easily and transmitting it further to the compression zone; (2) the material will be compressed due to increased inner volume; (3) the extrusion zone transmits the material further.

Cross-head extruders are used to produce combined (metal lined) profile bands.

Two cold perpendicular vacuum extruders are used with common cross-head to produce mixed, combined profile.

Extruder

Extruder

Co-Extruder

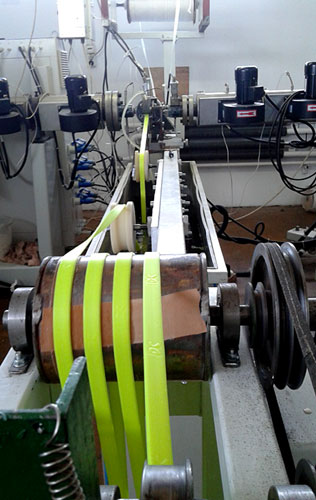

Extruder during operation

Extruder control panel

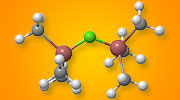

Extruder with ingredients